Matox Livestock Mats

Engineered for Australian Livestock and Production Systems

Anti Slip Easy Wash Long Life

Scroll down to request a free sample of our Matox Livestock Mat

Matox Features:

Highest abrasion resistance on the market

Anti slip, 360 degree directional grip

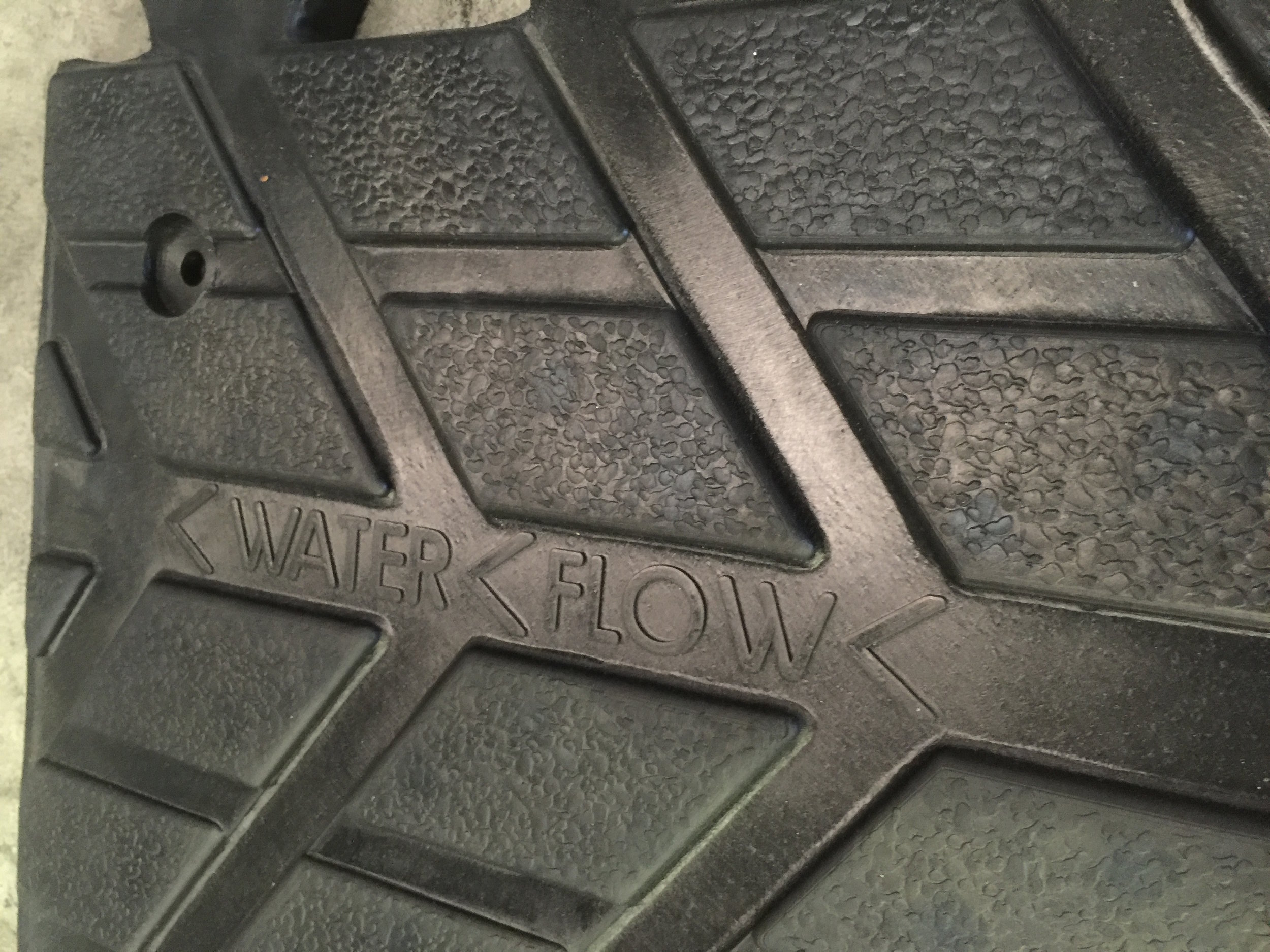

Easy wash water flow pattern

High compression and rebound capacity

Nylon interweave technology

Comes with marine grade stainless steel fixings with plugs and washers

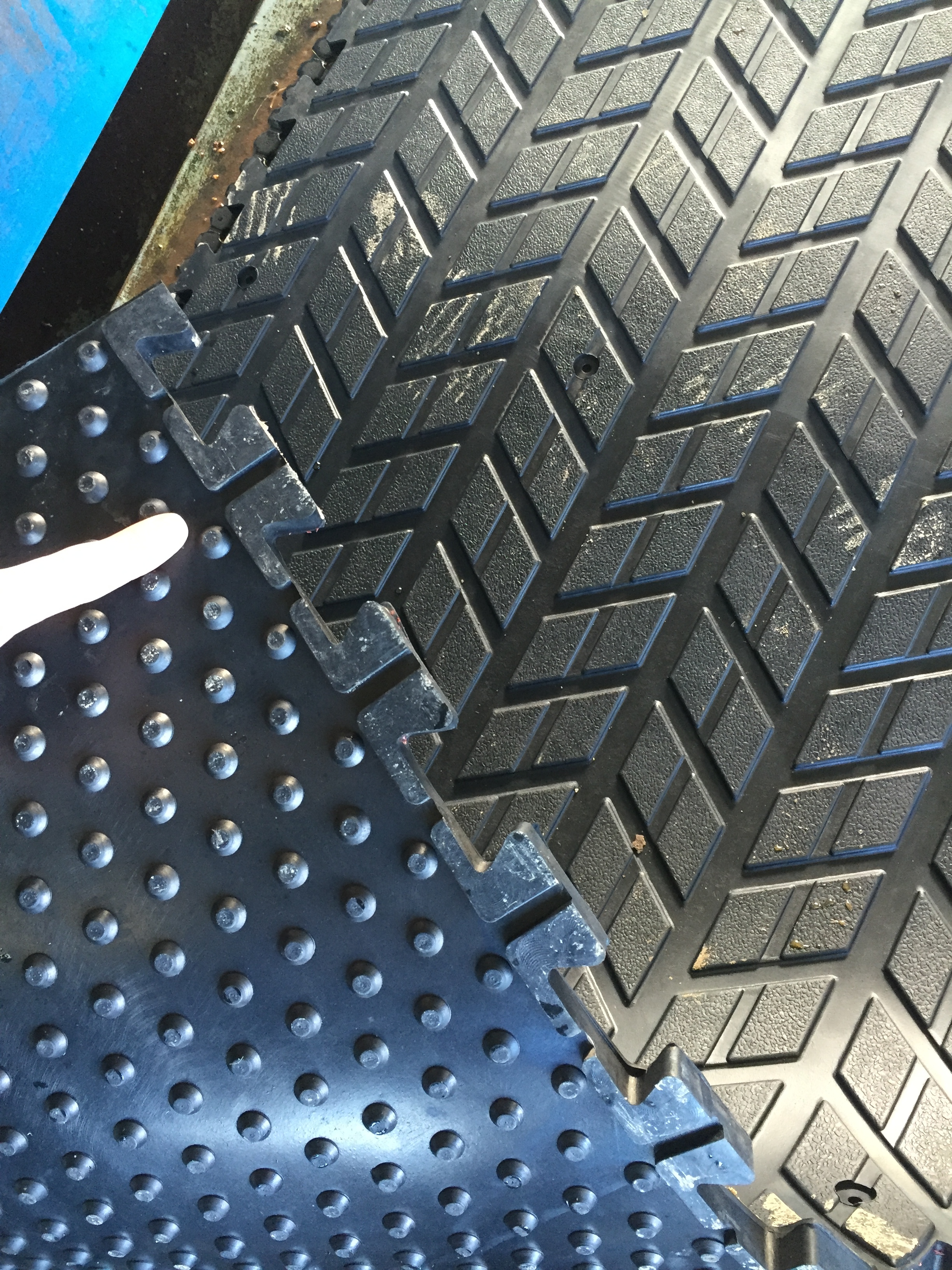

Stud underside

100% virgin natural rubber

Matox Benefits:

Stud underside for give and softness underfoot

Interlocking edge and drainage points

Reduced lameness

Improved animal health and performance

Water saving with flood wash / hose down

Increased cow flow (faster milking time)

Increased heat detection in yard

Improved employee safety and comfort underfoot

Easy wash water flow pattern

DIY easy install and uninstall (reversible screws)

Matox Testimonials:

"We're saving around 15 minutes on every milking due to improved cow flow. In addition, wash down time and water use has declined dramatically

The significant reduction in lameness and slipovers has seen herd health and production improve".

Justin Rendell, Australian Consolidated Dairies, Kyabram

Milking 850 cows twice per day, and an elite herd of 400 cows, three times a day

"We've tried a lot of mats, and find this mat extremely durable, high grip, easy to wash, and soft underfoot".

Bruce and Sam Holloway, Mepunga, Western Districts, Vic

Milking 400 cows twice per day

Matox Specifications:

Matox Performa Grip

1800mm long x 900mm wide

MPA quality rating - 10+

Thickness - 25mm

Long edge interlocking

Nylon interweave

Top surface "feather channel pattern"

Stud underside surface

Counter sunk screw fixing pattern

Fixings

12 x stainless steel 316 marine grade screw with plugs and washers (included)

Matox Installation Guide:

Step 1: Site Preparation Tips

Ideally, concrete thickness should be 50mm or greater

Repair any damaged concrete

Start with a washed down, clean concrete surface

When laying mats, make note of water flow direction during flood wash and hose down

Step 2: Tool Selection Tips

For screw bit, use a torx head T20 (6 point star shaped pattern)

Use high powered drill suitable for drilling and screwing into concrete

Concrete drill bit with four cutting tips. 10mm diameter x minimum working depth of 125mm

For shaping / cutting rubber, a Bosch soft material cutting blade T313AW/HCS is recommended. Alternatively, use a medium teeth hand saw

Step 3: Laying The Mat

Ideally, lay mats in brick formation making note of water flow indicator arrows

Fix top edge of the mats initially. Allow to acclimatise in layed position for 24 hours before fixing remaining mats

Ideally, fix mats during the warmest part of the day

When boring and screwing mats down, work down from the top of the pattern

Do not fix outside mats first or random mats down the pattern

To uninstall mats, simply reverse the drill

To request a sample, please fill out the below form